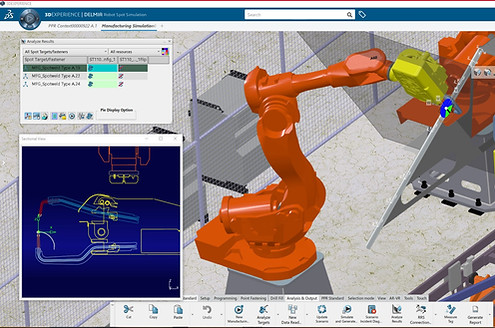

Robotics & Plant Simulation and Offline Programming

Choose from over 1500+ robots with pre-defined kinematics to define and validate new work cells with robots efficiently.

-

Includes Kuka, Fanuc, Motoman, Yaskawa, Nachi, Mitsubishi, and other major robot families

-

Built-In Workflows and PPR contexts to teach robots for Pick & Place, Spot Welding, Arc Welding, and Surface Painting operations

-

Reduce on-the-floor programming time with the Robotics Offline Programmer role

Custom Equipment Behavior and Kinematics

Import CAD as STEP or IGES from any CAD system and define equipment kinematics for custom tooling, machinery, and end-of-tool effectors to accurately conduct cycle time studies, reach studies, and clash.

Process Simulation (Line Builder) and Ergonomics

Validate assembly processes and operations for accurate performance estimates.

-

Conduct discrete event simulations to validate overall workstation cycle time

-

Run multiple iterations of the process to provide accurate and validated cycle time and performance estimates to your customers

-

Anticipate bottlenecks, resource timing, and human-machine interactions to define an ergonomically safe process

Go from CAD to a fully-defined work instructions with DELMIA on 3DEXPERIENCE

Explore how a simple CAD model can be used to create the MBOM, define manufacturing processes, and define work instructions with 3DEXPERIENCE On-Cloud.

.png)